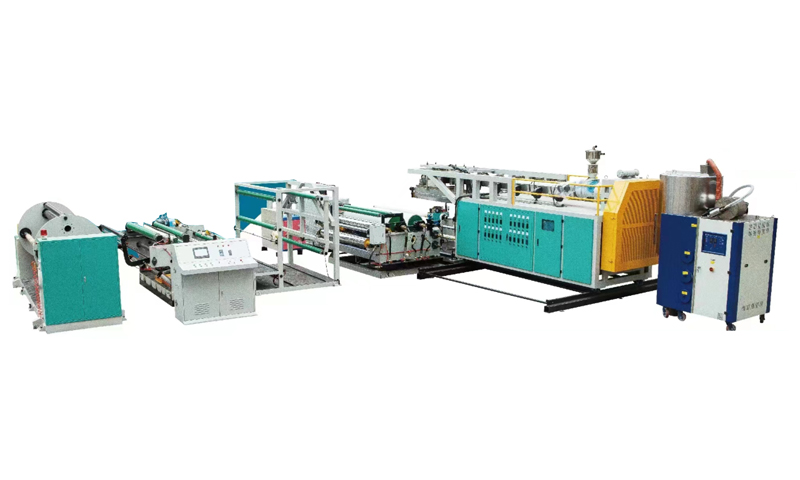

CPE Multiple Layer CO-Extrusion Cast Film Production Line

Iimpawu zomgca weMveliso

Iimpawu zomgca weMveliso

I-1) Ulwakhiwo lwe-Screw enomsebenzi odibeneyo wokudibanisa kunye nomthamo ophezulu weplastiki, iplastiki egqwesileyo, ukuxuba okusebenzayo, imveliso ephezulu;

2) Ulungelelwaniso lwe-T-die olukhethiweyo oluzenzekelayo oluzenzekelayo kwaye luxhotyiswe nge-APC yokulawula ubukhulu obuzenzekelayo, umlinganiselo we-intanethi wobunzima befilimu kunye nohlengahlengiso oluzenzekelayo lwe-T-die;

3)Umqulu wokwenza ukupholisa owenziwe ngembaleki ejikelezayo eyahlukileyo, eqinisekisa ukupholisa kwefilimu ngesantya esiphezulu;

4) Ukurisayikilishwa kwakhona kwi-intanethi kwezixhobo zomda wefilimu, okukhokelela ekuncitshisweni kweendleko zemveliso;

I-5) Ukubuyisela umva kwiziko elizenzekelayo, elixhotyiswe ngesilawuli sokuxinana esingeniswa ngaphandle, sivumela utshintsho oluzenzekelayo kunye nokusika, ukuququzelela ukusebenza ngokungenamgudu.

Umgca wemveliso usetyenziselwa ukuveliswa kwemigangatho emithathu ye-co-extruded CPE kunye nefilimu ye-CEVA.

Isicelo seMveliso

2. Izinto ezibalulekileyo zemihla ngemihla:Idyasi engenamanzi, iambrela yemvula, isigqubuthelo setafile yokutyela, ibhegi yesuti, ukhuseleko lwesandla, ifaskoti yokupheka, umkhusane webhafu, ikepusi yeshawara, njalo njalo.

3. Izinto zokusonga:Ityala lePC, umkhuseli wesixhobo sasekhaya, ikhaka lesihlangu, iphakheji yobuhle ethambileyo, ibhegi yokuthwala, isingxobo esikhoyo, isibambi serekhodi, isikhuseli sefayile, njalo njalo.

Idatha yoBugcisa

| Ububanzi obugqityiweyo | Ukutyeba okugqityiweyo | Mechanical Design isantya | Isantya esizinzileyo |

| 1600-2800mm | 0.04-0.3mm | 250m/min | 180m/mz |

Nceda uqhagamshelane nathi ngolwazi oluninzi lomatshini kunye nesiphakamiso. Singakuthumelela iividiyo zoomatshini ukuze uqonde ngokucacileyo.

Inkonzo yethu

Isithembiso seNkonzo yobuGcisa

Oomatshini benza uvavanyo kunye novavanyo lwemveliso kusetyenziswa imathiriyeli ekrwada ngaphambi kokuba ithunyelwe kumzi-mveliso.

Sinoxanduva lofakelo kunye nohlengahlengiso koomatshini, kwaye siya kubonelela ngoqeqesho kwiingcali zomthengi malunga nokusebenza koomatshini.

Ngexesha lonyaka omnye, xa kwenzeka ukuba naziphi na iinxalenye eziphambili ezingasebenziyo (ngaphandle kokuqhekeka okubangelwa yimiba yabantu kunye neendawo ezonakaliswe ngokulula), siya kuba noxanduva lokuncedisa umthengi ekulungiseni okanye ekutshintsheni iindawo.

Siza kubonelela ngenkonzo yexesha elide koomatshini kunye nokuthumela rhoqo abasebenzi ukuba batyelele ngokulandelelana ukunceda umthengi ekuxazululeni imiba ebalulekileyo kunye nokugcina umatshini.

Iworkshop kunye noomatshini

Ummandla weMveliso yoMthengi